| Availability: | |

|---|---|

| Quantity: | |

JH-FC030

Glorylab

8414609090

ASHRAE 110 Fume Hood Safety Fume Cupboard

Model: JH-FC030

Safety Performance:

Test results indicate no leakage (0.00ppm) at a face velocity of 0.5m/s, in compliance with the ASHRAE110-2016 US standard.

OSHA findings from 1990 revealed a startling statistic: laboratory personnel have an average lifespan 10 years shorter than the general population. This is directly linked to the leakage rate of fume hoods in laboratories.

The true measure of safety for a lab fume hood is its leakage rate, not just the face velocity.

Evolution of leakage rate standard of fume hood:

| Standard | Stipulated leakage rate |

| 1985 USA ASHRAE 110-1985 | 0.5 PPM |

| 1995 USA ASHRAE110-1995 | 0.05 PPM |

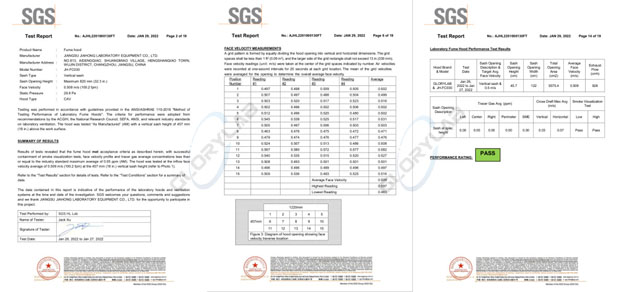

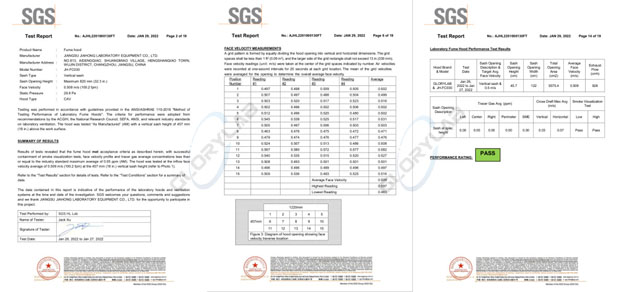

Test report:

Advantage

1. The true measure of the safety of a lab fume hood is its leakage rate, not just its surface velocity.

By optimizing the structure of the fume hood and applying aerodynamic principles, the studio can maintain a smooth airflow, reduce turbulence, and improve overall safety.

2. The exhaust hood designed specifically for fume hoods is made of refractory materials and can effectively remove harmful air.

3. Specially designed curved aluminum alloy handle ensures smooth airflow into the workspace.

Description:

Size: 1200/1500/1800x850x2350mm, custom sizes available.

Worktop:

Choose from a 19mm/25mm epoxy resin worktop with backsplash, or opt for lab-grade phenolic resin, trespa, or ceramic.

Exterior structure

1.0/1.2mm cold-rolled/galvanized steel sheet coated with epoxy resin powder after acid pickling, phosphating,oil and rust removing.

Interior structure

5mm compact/ceramic fiber panel which is chemical resistant and easy to be dismantled.

Sash

5mm toughened safety/anti-explosive glass,height can be adjustable. Sash can be moved horizontally if necessary. Long aluminum alloy handle is applied.

Storage cabinet

Door: double-layers structure with sound absorbing material inside,keeping noise minimum when door is opened or closed. U-shape128mm 304 stainless steel handle, long aluminum alloy grab handle. Acid and inflammable cabinets are available.

Color:White, gray, blue or specified by customer

PP cup sink:Polypropylene/ceramic/epoxy resin cup sink.

Standard accessories

Fluorescent lamp insulated from gas, LCD controller, TOF safe water&gas remote fitting equipped with pipeline and accessories.cup

sink, 4 universal/British/European/water proof socket. electrical leakage protection device.

Optional accessories

300W small centrifugal fan/3 meters PVC flexible pipe, France digital controller with sensor showing real face velocity and making alarm, sensitive VAV damper, auto-sash system.

Power supply:220/380V,50Hz

Face velocity:0.3~0.5m/s

Noise:<60dB

Diameter of exhaust outlet:250mm

Fluorescent lamp:30W

Standard:Ashrae110-2016, SEFA8M-2016

ASHRAE 110 Fume Hood Safety Fume Cupboard

Model: JH-FC030

Safety Performance:

Test results indicate no leakage (0.00ppm) at a face velocity of 0.5m/s, in compliance with the ASHRAE110-2016 US standard.

OSHA findings from 1990 revealed a startling statistic: laboratory personnel have an average lifespan 10 years shorter than the general population. This is directly linked to the leakage rate of fume hoods in laboratories.

The true measure of safety for a lab fume hood is its leakage rate, not just the face velocity.

Evolution of leakage rate standard of fume hood:

| Standard | Stipulated leakage rate |

| 1985 USA ASHRAE 110-1985 | 0.5 PPM |

| 1995 USA ASHRAE110-1995 | 0.05 PPM |

Test report:

Advantage

1. The true measure of the safety of a lab fume hood is its leakage rate, not just its surface velocity.

By optimizing the structure of the fume hood and applying aerodynamic principles, the studio can maintain a smooth airflow, reduce turbulence, and improve overall safety.

2. The exhaust hood designed specifically for fume hoods is made of refractory materials and can effectively remove harmful air.

3. Specially designed curved aluminum alloy handle ensures smooth airflow into the workspace.

Description:

Size: 1200/1500/1800x850x2350mm, custom sizes available.

Worktop:

Choose from a 19mm/25mm epoxy resin worktop with backsplash, or opt for lab-grade phenolic resin, trespa, or ceramic.

Exterior structure

1.0/1.2mm cold-rolled/galvanized steel sheet coated with epoxy resin powder after acid pickling, phosphating,oil and rust removing.

Interior structure

5mm compact/ceramic fiber panel which is chemical resistant and easy to be dismantled.

Sash

5mm toughened safety/anti-explosive glass,height can be adjustable. Sash can be moved horizontally if necessary. Long aluminum alloy handle is applied.

Storage cabinet

Door: double-layers structure with sound absorbing material inside,keeping noise minimum when door is opened or closed. U-shape128mm 304 stainless steel handle, long aluminum alloy grab handle. Acid and inflammable cabinets are available.

Color:White, gray, blue or specified by customer

PP cup sink:Polypropylene/ceramic/epoxy resin cup sink.

Standard accessories

Fluorescent lamp insulated from gas, LCD controller, TOF safe water&gas remote fitting equipped with pipeline and accessories.cup

sink, 4 universal/British/European/water proof socket. electrical leakage protection device.

Optional accessories

300W small centrifugal fan/3 meters PVC flexible pipe, France digital controller with sensor showing real face velocity and making alarm, sensitive VAV damper, auto-sash system.

Power supply:220/380V,50Hz

Face velocity:0.3~0.5m/s

Noise:<60dB

Diameter of exhaust outlet:250mm

Fluorescent lamp:30W

Standard:Ashrae110-2016, SEFA8M-2016

content is empty!